Time:2024-07-10 16:59:11

We help you built your project

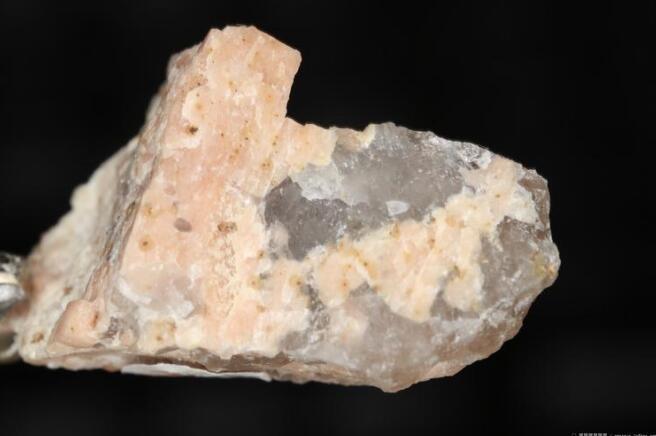

Plagioclase ultrafine grinding mill is designed to grind the mineral into very fine particles, often in the micron or even nanometer range. These mills are particularly useful in industries requiring extremely fine powders, such as in high-tech ceramics, advanced composites, and certain chemical processes. Here are some details about ultrafine grinding mills suitable for plagioclase:

Types of Ultrafine Grinding Mills

l Description: Utilize multiple rollers to grind materials against a grinding table. Equipped with sophisticated controls for fine-tuning particle size.

l Applications: Ideal for producing ultrafine powders, including plagioclase, with high efficiency and consistent quality.

l Advantages: Energy-efficient, consistent particle size distribution, and lower operational costs.

l Description: Use a stirring mechanism to move the grinding media (ceramic or steel balls) and the material being ground. These mills achieve ultrafine grinding by constant agitation.

l Applications: Suitable for achieving very fine particle sizes for plagioclase and other minerals.

l Advantages: High energy efficiency, capable of producing nanoparticles, and effective for materials with varying hardness.

l Description: Use high-velocity jets of air or steam to collide particles against each other, achieving ultrafine grinding. No moving grinding media are involved, reducing contamination.

l Applications: Ideal for ultrafine grinding of heat-sensitive materials and those requiring high purity, like plagioclase.

l Advantages: Produces extremely fine powders, minimal contamination, and no heat generation during grinding.

l Description: Modified ball mills equipped with fine grinding media and optimized for ultrafine grinding.

l Applications: Can achieve fine and ultrafine grinding by using appropriate media and conditions.

l Advantages: Versatile and capable of achieving very fine particle sizes with proper adjustments.

l Description: Combines the principles of a vertical roller mill and an ultrafine grinding mill, often used for materials requiring ultrafine particle sizes.

l Applications: Suitable for large-scale production of ultrafine plagioclase powder.

l Advantages: High throughput, energy efficiency, and precise control over particle size.

1. Particle Size Distribution: Ensure the mill can achieve the desired fineness and maintain a narrow particle size distribution.

2. Material Hardness: Plagioclase hardness (6-6.5 on the Mohs scale) should match the mill's capabilities.

3. Contamination Control: Use mills designed to minimize contamination, especially important for high-purity applications.

4. Energy Efficiency: Consider the energy consumption of the mill, particularly for large-scale production.

5. Operational Costs: Evaluate initial investment, maintenance, and operational costs.

1. Advanced Ceramics: Used in the production of high-strength and high-purity ceramics.

2. Coatings and Polishes: Provides fine particles for smooth, high-quality finishes.

3. Electronics: Involved in manufacturing components requiring precise mineral compositions.

4. Pharmaceuticals: Used as an excipient in drug formulations.

5. Nanocomposites: Utilized in materials science for enhancing composite properties.

CLUM Ultrafine Vertical Roller Mill

High efficiency, low operation cost, and fine particle size control.

Known for high throughput, fine particle size distribution, and energy efficiency.

Selecting the appropriate ultrafine grinding mill for plagioclase involves understanding the specific requirements of the application and the properties of the mineral. These mills provide the capability to produce extremely fine powders with high purity and efficiency.

ALL RIGHTS RESERVED ? CLIRIK technology and cloud computing service support-91 Internet