Pebbles, granite sand, cement limestone broken, they all need to be crushed by

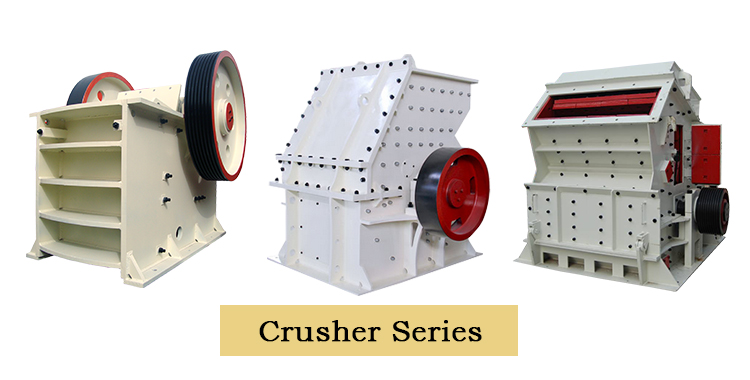

Stone Crusher Plant, so the crusher equipment status is more and more important. Shanghai Clirik supply jaw crusher, Germany BHS sand making machine, hammer crusher, impact crusher and aggregate production line, getting the customer's praise.

With the continuous improvement of technology, bulky crusher has been unable to meet the needs of intensive production, the market of intelligent equipment is getting wider and wider. The intelligence of Clirik crusher mainly lies in the following aspects:

1, automatic optimization, intelligent matching

Crusher products are equipped with the corresponding data algorithms and production process data, according to fast data feedback of feeding, crushing, screening, conveying, we can adjust the operation of the corresponding equipment, so as to achieve the ideal matching production status of each module.

2, early warning state monitoring

The equipment current, bearing temperature, equipment vibration, pressure and other testing, we should make timely feedback, early warning and protection.

3, remote monitoring

Stone crushing production line is equipped with remote monitoring system, ready to readily understand the production situation and site conditions, through mobile phones, tablet PCs and other electronic tools. According to on-site feedback, we make timely communication, which make it easy to manage.

4, ERP system

According to customer requirements, The contents of the ERP management system can be set, and data archiving and remote feedback is done.