Time:2023-04-24 15:24:45

We help you built your project

Kyanite is a silicate mineral with an island structure, usually in the form of flat columnar crystals, with parallel stripes on the crystal surface, and the color is light blue, cyan, bright off-white, etc. It has strong chemical corrosion resistance, thermal shock mechanical With high strength and irreversible thermal expansion, it is the main raw material for the production of amorphous materials and electric furnace roof bricks, phosphate unfired bricks, mullite bricks, and low-creep bricks.

After rough kyanite ore is crushed by jaw crusher, impact crusher is usually used for shaping and fine crushing. CLIRIK has optimized and improved the traditional impact crusher, combined with the mineral properties of kyanite, and produced a new type of equipment—kyanite impact crusher, which has remarkable performance characteristics and has been favored by many customers.

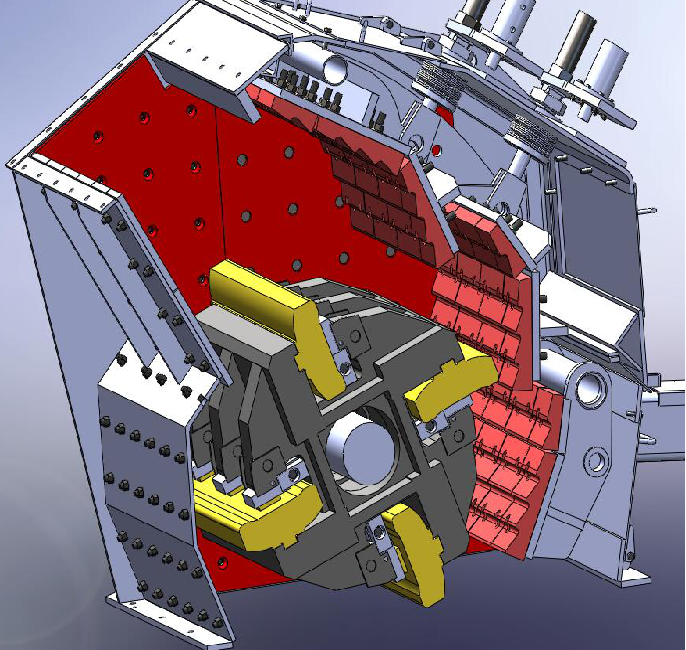

Kyanite impact crusher is mainly composed of body, high-speed motor, transmission device, cavity liner, rotor, liner, blow bar, impact plate and other components. The rotor is fixed on the main shaft, and three blow bars are installed on the surface of the rotor. There are two front and rear impact plates hung on the inner wall of the casing above the rotor, and a curtain composed of many chains is hung between the impact plate and the feeding port.

When working, driven by the motor, the rotor rotates at a high speed, kyanite is fed from the feed port, and slides down along the feed sieve plate, and is pressed by the blow bar on the high-speed rotating rotor during the falling process. After being crushed and obtained extremely high kinetic energy, it flies toward the counterattack plate along the tangent direction at high speed. After being hit and broken by the counterattack plate again, it is rebounded by the counterattack plate and collides with the ore thrown out by the rotor. The same crushing process in one cavity will meet the discharge granularity and be discharged from the bottom discharge port.

1. The counterattack plate is welded by steel plates, and the counterattack surface is equipped with a wear-resistant lining plate, which is not easy to wear and easy to replace.

2. Adopt high-precision bearing sealing lubricating oil system, no oil leakage, and can effectively prevent dust from entering the machine.

3. The jacking device can quickly open the rear frame, and at the same time, the rotor and the main shaft are connected by an expansion sleeve without a key, which is convenient for maintenance, economical and reliable.

4. The maintenance door is equipped with a safety interlock system, which can prevent the maintenance door from being opened during operation and the machine from being turned on during maintenance.

5. The structure of the uniform board makes the discharge have a small particle size and a cubic shape without internal lines, and the discharge particle size can be flexibly adjusted.

ALL RIGHTS RESERVED ? CLIRIK technology and cloud computing service support-91 Internet